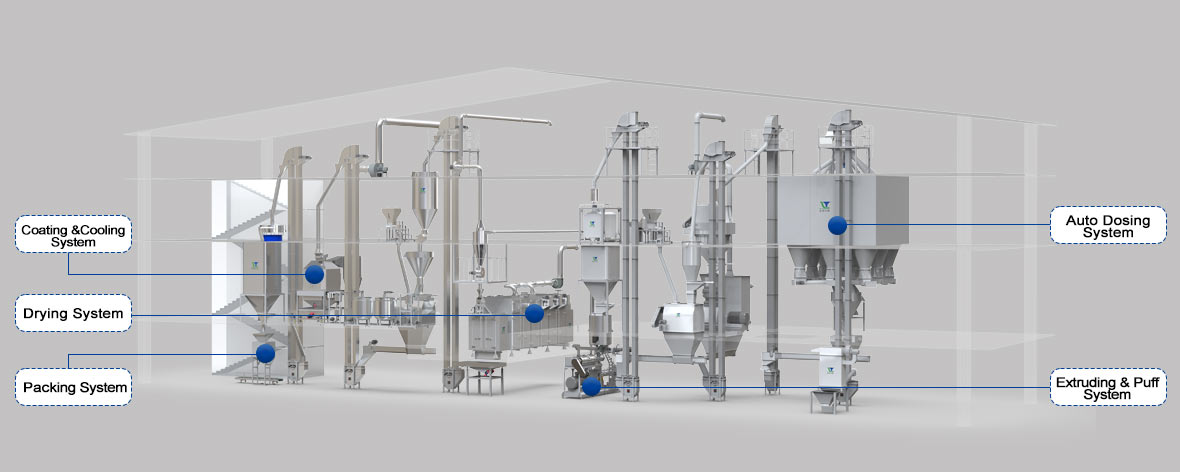

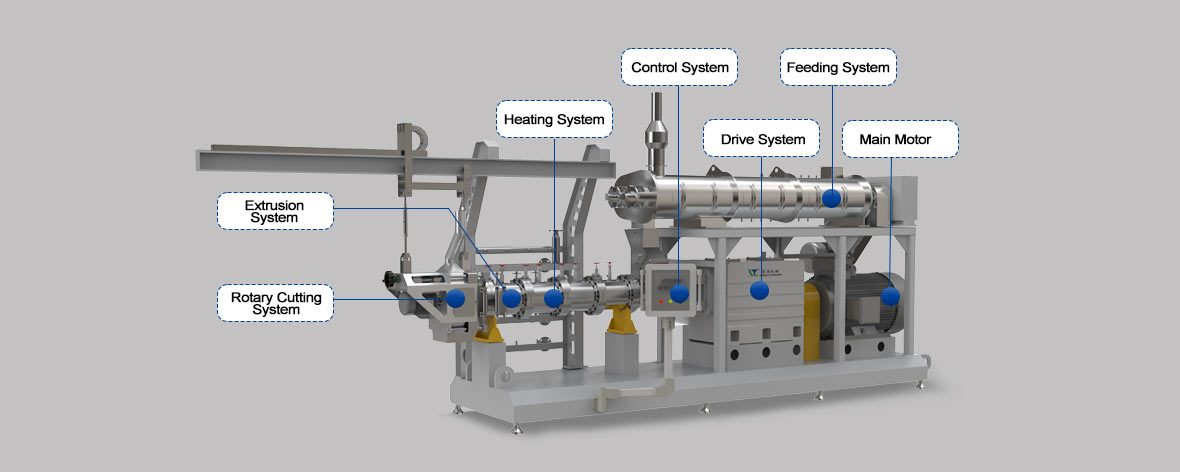

A dry pet food extrusion line is a series of machines and equipment that are used to produce dry pet food. Animal Feed Process Line mainly uses meat meal, fish meal, bone powder corn powder, soya meal, and other grains powder as the main materials to produce innovative shapes, high nutritional and savory taste pet food for dogs, cats, foxes, birds, etc.

To find out more details about Pet Food Extrusion Line, contact us NOW

To find out more details about Pet Food Extrusion Line, contact us NOW