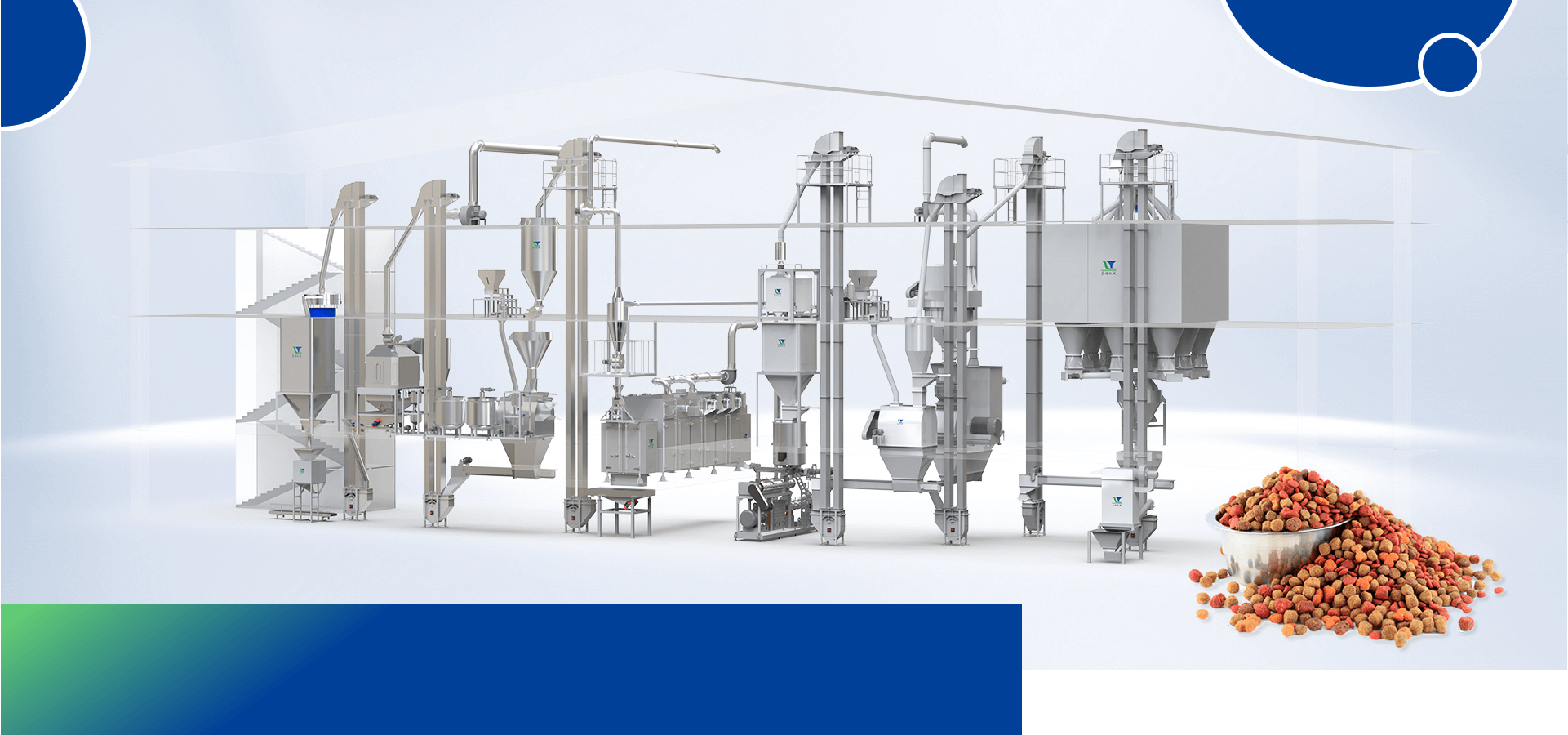

Commercial granular dog food is the most commonly used pet food by pet lovers, but how is it produced? Is it safe for dogs to eat? This is a question that most pet lovers care about.

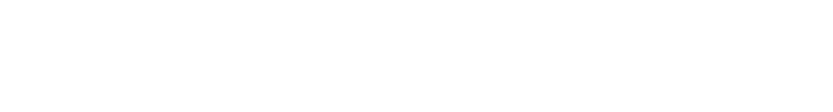

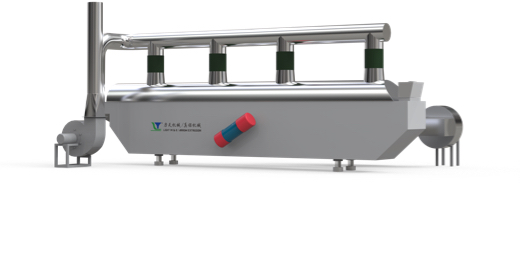

Rice is a widely consumed staple food in China and other parts of the world. However, during the rice processing, most of the nutrients are lost. The need for fortified rice has been emphasized for many years, especially in poor and remote areas where people suffer from serious nutritional problems.

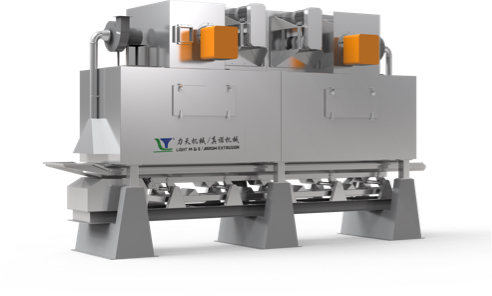

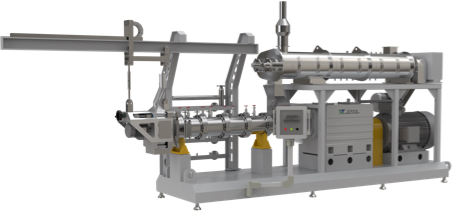

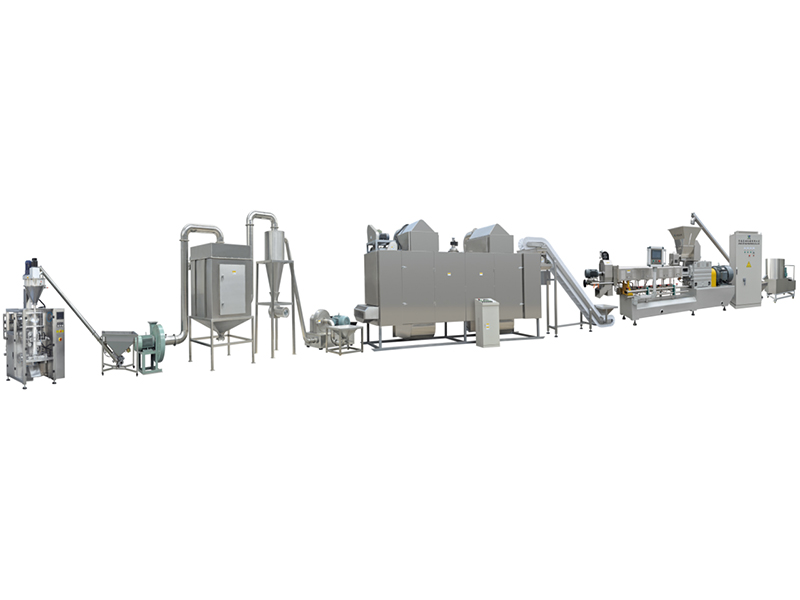

When choosing a pet food extruder, the following factors should be considered:Production capacity: Choose a pet food extruder with suitable production capacity according to your production needs. If you are a small production enterprise, you can consider purchasing a small and medium pet food extrud

Samy is the owner of a company headquartered in Saskatchewan, Canada, that specializes in the production of the pulse-derived meal, protein, starch, and fiber for use in food ingredients and branded feed products. The company is one of the world's largest suppliers of beans, staple foods, and food i

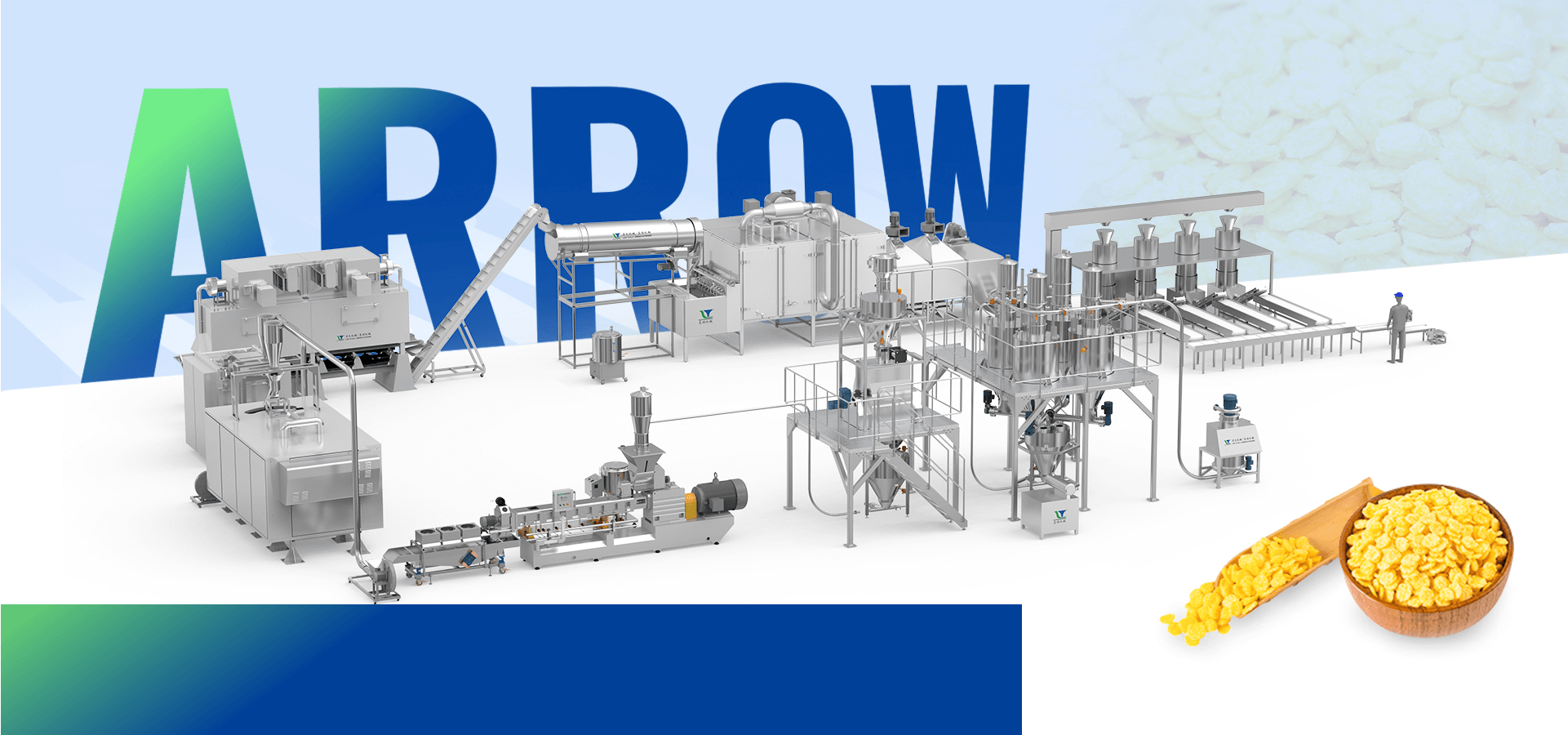

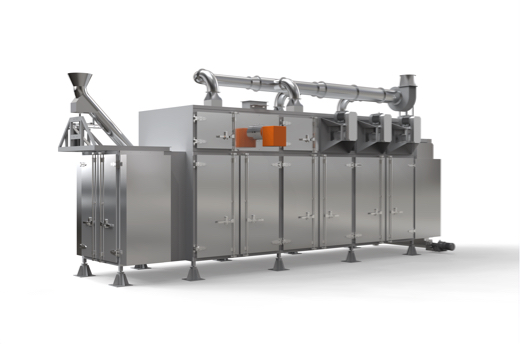

Diana, a businesswoman from Zambia, Africa, reached out to us 10 years ago to start her own snack production business. After careful consideration and comparison, she ultimately decided to purchase a common standard LT70 puffed line from us, with a production capacity of 200-250kg.Considering that D

When we first met Mr. Rafael at an exhibition, he was struggling with his old double screw extruder and had stopped producing snack food. However, we saw an opportunity to help him reuse his existing equipment and expand his production capabilities. We designed a special machine that would allow him

Mr. Joseph, the new customer of Arrow Machine company, was facing problems with the operation of the machines he had purchased from another supplier. He was unable to get good after-sales service from his previous supplier, but after several days of communication and discussion with our engineer, Mr

Baby rice powder is based on the nutritional needs of different stages of infant growth and development, using high-quality rice as the main raw material, plus milk powder, egg yolk powder, soybean powder, vegetable oil, sucrose, etc., after crushing, grinding, high temperature sterilization and oth