| Availability: | |

|---|---|

| Quantity: | |

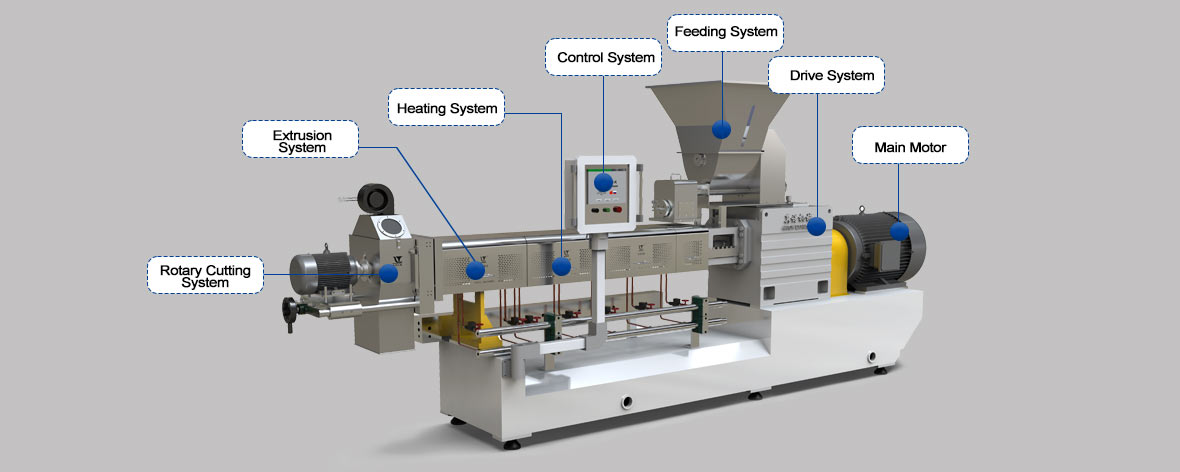

Food Extrusion Technology - LT series Common Standard Twin Screw Extruder

Twin screw food extruder is a new food processing technology, materials are extruded and cut, and mixed by the screw in the machine barrel. The material is fully matured under high temperature and pressure, through the outlet mold expansion, forming foods of various shapes.Twin screw food extruder is a type of food processing machinery that uses two screws to mix, knead, and shape food materials. The screws rotate in opposite directions within a barrel, creating friction and heat that cooks and matures the food as it is extruded through a die. The twin screw design allows for greater control over the mixing and shaping of the food materials, as well as the ability to add in ingredients, such as vitamins and minerals, during the extrusion process. Twin screw food extruders are commonly used in the production of snack foods, cereals, pet food, and other food products. They are known for their high efficiency, flexibility, and ability to produce a wide variety of shapes and textures.

Technical Parameters of LT Series Twin Screw Food Extruder

Model | Main drive power | Output | Products |

S85/LT85 | 75KW | 500kg/h | Snacks\ breakfast cereals\corn flakes\ pet food\ Fried -semi-puff snacks \nutrition rice\ 70L model Water-Cooling System Applied, Available for Different Extrusion Temperature Products |

LT70 | 37KW | 220-250kg/h | |

LT70L | 37KW | 200-250kg/h | |

LT65L | 30KW | 150-180kg/h | |

LT65 | 22KW | 120-150kg/h |

What is this LT Series Twin Screw Food Extruder Used for?

Twin screw food extruders are commonly used in the pet food industry to produce high-quality, nutritious, and palatable food for animals such as dogs, cats, birds, and foxes. The main materials used in these extruders include meat meal, fish meal, bone powder, corn powder, soya meal, and other grain powders. These ingredients are combined and processed using the extruder to create a wide variety of shapes, textures, and flavors that are appealing to pets. Additionally, these extruders also can add vitamins, minerals, and other nutrients, to improve the nutritional value of the final product.

Main Features-LT Series Food Extrusion Machinery

Twin Screw Food Extruder is advanced extrusion machinery used for food processing, specifically for producing expanded products such as snacks or cereals.

The main components of the machine include a feeding system, extruding system, cutting system, heating system, lubricating system, and controlling system. These systems work together to process the raw materials and produce the final product.

The use of frequency conversion timing in the feeding system, extruding system, and cutting system allows for a powerful drive, stable performance, and energy savings.

The screws are made of alloy and are treated with a special technique to increase their strength, resistance to wear, and longevity.

The barrel with water-cooled circulation allows the extruder to handle raw materials with high viscosity, such as wheat flour or starch, in addition to corn and rice. This feature also allows for different moisture-extrusion temperature ratios, which can be used to produce different types of products, such as whole-expanded and half-expanded. This feature allows for greater flexibility in the production process and can lead to improved product quality.

Advantages-LT Series Twin Screw Food Extruder

1. The screw is a combination modular structure, which can be assembled in any combination to meet different formulas and product requirements.

2. The screw and the screw pieces are made of a special alloy with high strength and high wear resistance.

3. The screw adopts a fully engaged model, designed by 3D design, CNC machining, smooth surface, high conjunction accuracy, and better self-cleaning function, changing parts flexibly.

4. The barrel is a combination of the modular circular structures. Increased ( or reduced) is very flexible and convenient.

5. Heating and cooling medium circulation of the internal are optimized to ensure that the temperature control is sensitive and the internal and external temperature difference is small.

6. Heating and cooling medium of each barrel can be controlled independently.

7. Bushing with wear-resistant alloy material, long use life.

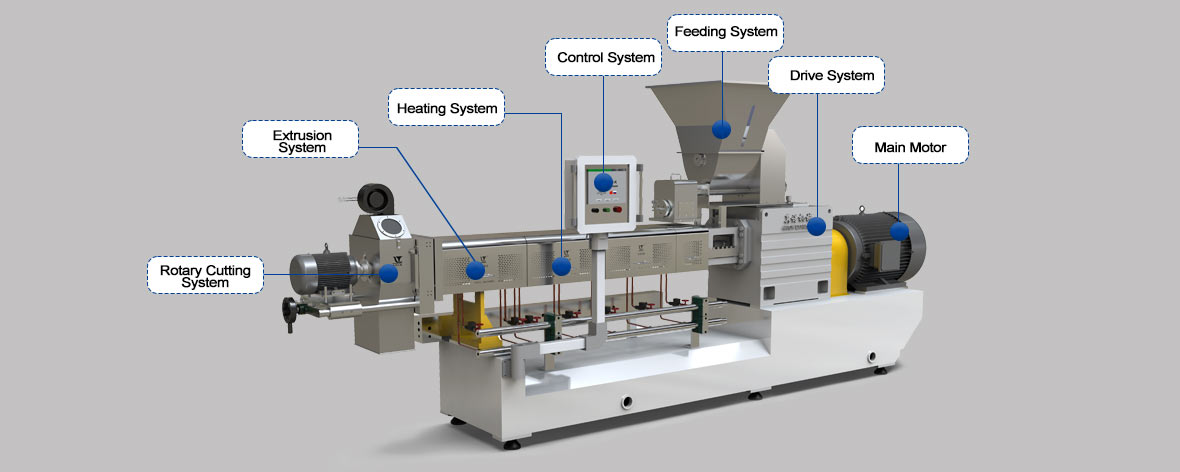

Food Extrusion Technology - LT series Common Standard Twin Screw Extruder

Twin screw food extruder is a new food processing technology, materials are extruded and cut, and mixed by the screw in the machine barrel. The material is fully matured under high temperature and pressure, through the outlet mold expansion, forming foods of various shapes.Twin screw food extruder is a type of food processing machinery that uses two screws to mix, knead, and shape food materials. The screws rotate in opposite directions within a barrel, creating friction and heat that cooks and matures the food as it is extruded through a die. The twin screw design allows for greater control over the mixing and shaping of the food materials, as well as the ability to add in ingredients, such as vitamins and minerals, during the extrusion process. Twin screw food extruders are commonly used in the production of snack foods, cereals, pet food, and other food products. They are known for their high efficiency, flexibility, and ability to produce a wide variety of shapes and textures.

Technical Parameters of LT Series Twin Screw Food Extruder

Model | Main drive power | Output | Products |

S85/LT85 | 75KW | 500kg/h | Snacks\ breakfast cereals\corn flakes\ pet food\ Fried -semi-puff snacks \nutrition rice\ 70L model Water-Cooling System Applied, Available for Different Extrusion Temperature Products |

LT70 | 37KW | 220-250kg/h | |

LT70L | 37KW | 200-250kg/h | |

LT65L | 30KW | 150-180kg/h | |

LT65 | 22KW | 120-150kg/h |

What is this LT Series Twin Screw Food Extruder Used for?

Twin screw food extruders are commonly used in the pet food industry to produce high-quality, nutritious, and palatable food for animals such as dogs, cats, birds, and foxes. The main materials used in these extruders include meat meal, fish meal, bone powder, corn powder, soya meal, and other grain powders. These ingredients are combined and processed using the extruder to create a wide variety of shapes, textures, and flavors that are appealing to pets. Additionally, these extruders also can add vitamins, minerals, and other nutrients, to improve the nutritional value of the final product.

Main Features-LT Series Food Extrusion Machinery

Twin Screw Food Extruder is advanced extrusion machinery used for food processing, specifically for producing expanded products such as snacks or cereals.

The main components of the machine include a feeding system, extruding system, cutting system, heating system, lubricating system, and controlling system. These systems work together to process the raw materials and produce the final product.

The use of frequency conversion timing in the feeding system, extruding system, and cutting system allows for a powerful drive, stable performance, and energy savings.

The screws are made of alloy and are treated with a special technique to increase their strength, resistance to wear, and longevity.

The barrel with water-cooled circulation allows the extruder to handle raw materials with high viscosity, such as wheat flour or starch, in addition to corn and rice. This feature also allows for different moisture-extrusion temperature ratios, which can be used to produce different types of products, such as whole-expanded and half-expanded. This feature allows for greater flexibility in the production process and can lead to improved product quality.

Advantages-LT Series Twin Screw Food Extruder

1. The screw is a combination modular structure, which can be assembled in any combination to meet different formulas and product requirements.

2. The screw and the screw pieces are made of a special alloy with high strength and high wear resistance.

3. The screw adopts a fully engaged model, designed by 3D design, CNC machining, smooth surface, high conjunction accuracy, and better self-cleaning function, changing parts flexibly.

4. The barrel is a combination of the modular circular structures. Increased ( or reduced) is very flexible and convenient.

5. Heating and cooling medium circulation of the internal are optimized to ensure that the temperature control is sensitive and the internal and external temperature difference is small.

6. Heating and cooling medium of each barrel can be controlled independently.

7. Bushing with wear-resistant alloy material, long use life.