Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

As production scales up, many pet food manufacturers face challenges such as inconsistent product quality, rising operational costs, and increasing regulatory pressure. These issues directly impact profitability in export markets and brand reputation. With global demand continuing to grow, understanding the pet food production process has become essential. This article systematically explains modern pet food manufacturing methods and how process control addresses these challenges.

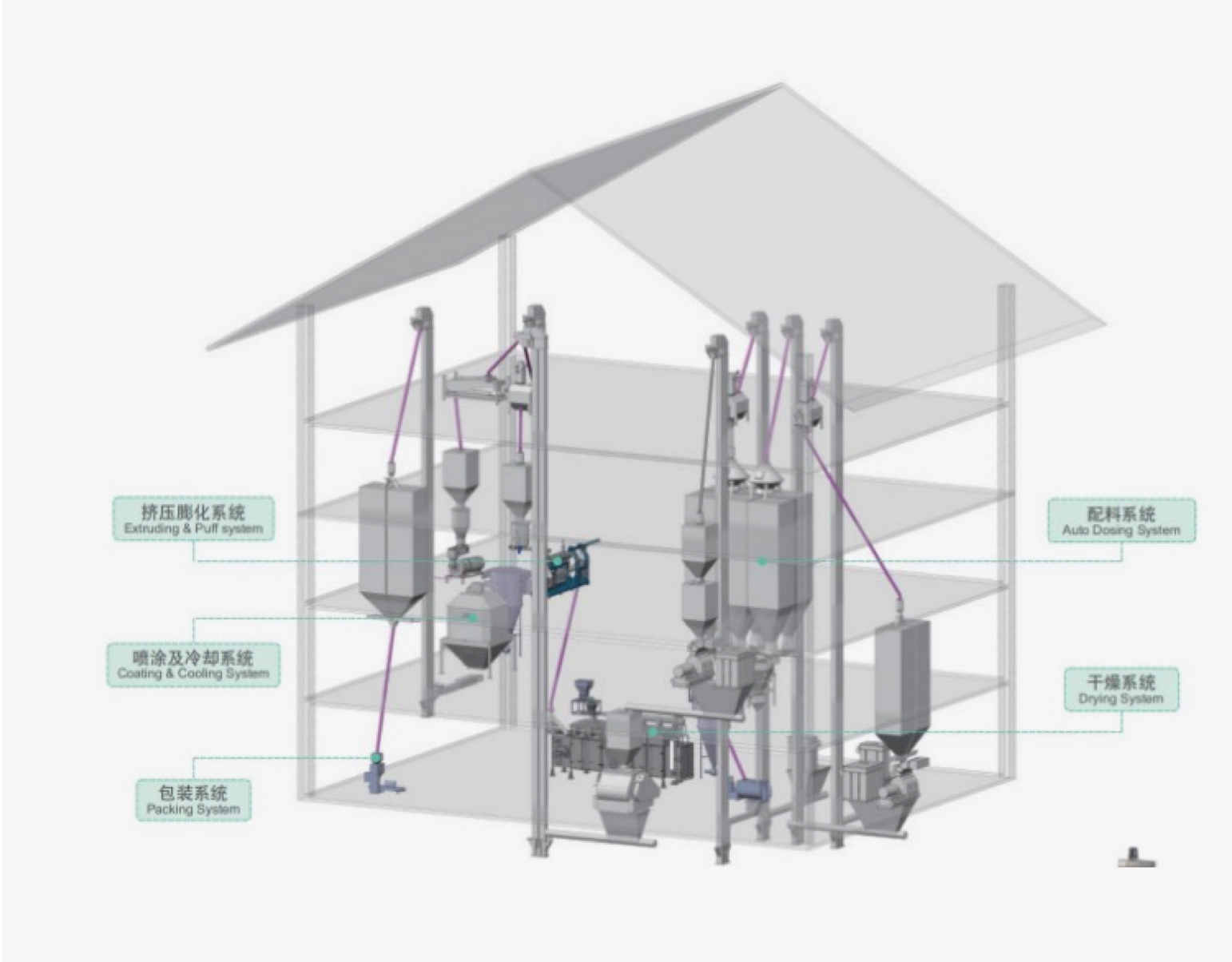

The pet food production process includes raw material preparation, grinding, mixing, extrusion cooking, drying, coating, cooling, and packaging. Industrial pet food production lines rely on extrusion technology to ensure food safety, nutritional consistency, and scalable manufacturing capabilities. By optimizing each processing stage, manufacturers can improve product quality, reduce costs, and efficiently meet international pet food standards.

A superficial understanding of pet food production is no longer sufficient; manufacturers must closely examine every production stage to remain competitive, compliant, and profitable in today’s global pet food market.

The pet food manufacturing industry is often underestimated by new investors and even some experienced processors. While the final product may seem simple, the production process is technically demanding and highly sensitive to operational variables.

A common issue is inconsistent kibble quality. Variations in particle size, density, expansion rate, and moisture content are typically caused by improper control of grinding fineness, extrusion parameters, or drying conditions. These instabilities directly affect palatability and shelf life, leading to increased consumer complaints.

Another persistent problem is high production cost per ton. Many factories still use outdated equipment or have low integration in their production lines. High energy consumption, excessive labor input, and frequent downtime significantly reduce overall efficiency.

Food safety presents another major challenge. Pet food must meet increasingly stringent international standards. Any flaws in thermal processing or hygienic design increase the risk of contamination and audit failures.

The urgency to optimize pet food production processes is driven by several market realities.

First, global pet food consumption is rapidly growing. Industry data shows that dry pet food accounts for over 70% of total global pet food volume, making extrusion-based production lines the industry standard.

Second, raw material price fluctuations continue to squeeze profit margins. Prices for protein meals and oils are highly volatile. Low production efficiency leads to higher waste rates and reduced profitability.

Third, regulatory scrutiny is intensifying. Export-oriented manufacturers must pass multiple inspections related to hygienic design, traceability, and nutritional consistency. Factories with unstable production processes face higher rejection rates and longer certification cycles.

From a practical standpoint, manufacturers that fail to optimize their production processes often struggle to scale, regardless of market demand.

A well-designed pet food production process addresses these challenges through standardization, automation, and precise control. Below is a step-by-step explanation of how modern dry pet food is produced in industrial facilities.

The process begins with raw material selection. A typical formula includes animal protein meals, grains, plant proteins, fats, and micronutrients.

Accurate dosing is critical. Automated weighing systems ensure precise formulas and reduce human error.

Industry Insight:

In factories with hourly output exceeding 3 tons, manual dosing often results in formula deviations of over ±2%, directly affecting extrusion stability.

Typical Raw Material Composition (Dry Dog Food Example)

Ingredient Category | Percentage Range |

Animal Protein | 20–35% |

Grains/Starch | 30–50% |

Plant Protein | 5–15% |

Fats | 5–10% |

Vitamins & Minerals | 1–3% |

A hammer mill is used to crush raw materials to achieve uniform particle size, typically between 200–600 microns.

Particle size directly impacts extrusion performance:

Particle Size | Impact on Extrusion |

Too Coarse | Poor cooking, low expansion |

Optimal | Stable pressure, uniform texture |

Too Fine | High torque, clogging risk |

Experienced manufacturers treat grinding as a process control step, not just preparation.

Ground materials are mixed with water, steam, and micro-additives. Even mixing ensures consistent nutrition and appearance.

Pre-conditioning partially gelatinizes starch before extrusion, increasing output and reducing mechanical wear on the extruder screws.

Subjective Opinion:

Based on long-term operating data, factories using pre-conditioners typically increase output per ton by 10–15% while reducing energy consumption.

Extrusion is the most critical stage. Materials are processed under controlled temperature, pressure, and shear force.

Key Extrusion Parameters

Parameter | Typical Range |

Temperature | 110–160°C |

Moisture | 18%–28% |

Screw Speed | 300–600 rpm |

Twin-screw extruders are widely used by export-focused factories due to their superior flexibility and formulation tolerance.

Real Case:

A pet food factory in Southeast Asia upgraded from a single-screw to a twin-screw extruder, reducing product defect rate by over 30% within six months.

As the product exits the die, rotating blades cut the kibble into precise lengths. Visual consistency is crucial for brand perception.

Unstable cutting often indicates upstream pressure fluctuations, signaling the need for extruder adjustments.

Drying reduces moisture content from 20–25% down to 8–10%.

Drying Performance Targets

Parameter | Target Value |

Final Moisture | 8–10% |

Drying Time | 20–45 minutes |

Temperature | 80–130°C |

Improper drying is a leading cause of shortened pet food shelf life.

Coating enhances palatability and energy density. Fats and flavor enhancers are added after drying to avoid heat degradation.

Vacuum coating systems are increasingly popular in premium pet food production.

Industry Observation:

Products using vacuum oil infusion generally have higher repeat purchase rates, especially in the cat food segment.

Cooling stabilizes product structure and prevents condensation. Packaging systems weigh, seal, and label the product for distribution.

Stepwise automation can reduce labor costs and improve consistency—especially important for export shipments.

The pet food production process is not a single machine operation but a fully integrated production system. From raw material handling, extrusion, drying, and coating to packaging, each step directly affects product quality, safety, and cost structure.

From a B2B perspective, manufacturers who invest in process optimization can consistently lower operational costs, improve product consistency, and enhance export competitiveness. In practice, understanding and controlling the production process is one of the most reliable ways to achieve long-term success in the global pet food industry.

If you're planning to build or upgrade a pet food production line, partnering with an experienced, export-focused equipment supplier can significantly reduce technical risks and investment costs. Jinan Arrow Machinery Co., Ltd.specializes in turnkey solutions for pet food production lines, covering process design, equipment manufacturing, installation, commissioning, and operator training. Our systems are running reliably in 118 countries and regions worldwide.

Email: arrow@znmachinery.com

Contact our technical team today to discuss your raw materials, target capacity, and market needs. We can tailor an efficient, cost-effective pet food production solution for your factory.